selection of crusher depending on application

2022-06-08T19:06:38+00:00

Selecting the right crusher for your operations – Quarry

Mar 19, 2020 Best suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher Cone crushers can form finished products down to 12mm or lessStone Crusher E Tec The large selection of devices of stonecrushers and soiltillers series by seppi makes it possible depending on the tractor and application to find the right device for your own needss diverse as the various models are the application possibilities crushing stones on farmland and paths building and maintaining forest roads stabilizing the soil for roadselection of crusher depending on applicationBest suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm, or 200mm, depending on the size of the crusher Cone crushers can form finished products down to 12mm or lessSelecting the Right Crusher for Quarry Operations AggNet

Choosing the right cone crusher for your application – Quarry

Rather, all three types of cone crushers can work but some are more suited to some applications than others Depending on the type of material being processed and the desired output in terms of tonnage or specification, extractive producers have the opportunity to select from any one of the three styles of conesCrusher Selection While crushing is governed by basic laws of physics, no single law or rule take the place of experience and testing in the selection and sizing of a suitable crusher for a given application selection criteria of crusher ecoopeuselection of crusherShort head liners are used in tertiary or quaternary stage applications for fine crushing and may be in closed circuit returning to the crusher Liners are manufactured from XT510,XT515, XT520, XT525, XT710, XT750 or XT770 material depending on the application and material characteristics MP Series Cone Wear Parts Selection Guide

Crushing Equipment Selection

In open pit quarry operations the loading of the blasted rock for transportation to the primary crusher house involves either powershovels Any size of primary crusher may be used for handloaded rock; it all depends upon how much secondary shooting, and hand sledging, the operator feels he can afford So called “oneman” stone or stone of a size that can be lifted into small cars or Selection of the type of crusher and the crushing process for any application depends on material hardness, and density of the material, feed size, desired product size, and capacity needs; as well as initial costs for each crusher and the cost to maintain each style of crusher Basic Construction and Working Principle:What is the difference between a Cone Crusher and an If a singlestage reduction is required, then depending on the feedtoproductsize ratio of reduction, either a Single or Double Roll Crusher can be selected Regardless of the crusher type selected, Roll Crushers allow for the material to fracture along naturally occurring cleavage lines, which helps with minimizing fines generationRoll Crushers McLanahan

5 Steps To Choose Best Motor For Your Application

Sizing a motor for these applications is simple once the torque (or horsepower) for the application is known Load demands by elevators, compactors, punch presses, saws, and batch conveyors change abruptly from low to high in a short time, often in a fraction of a secondOct 17, 2019 When choosing the best crusher for your primary, you first have to consider the application details Desired product size, capacity, HGI, percentage of rock, and hardness of the rock in the feed are some of the factors that dictate the selection of primary crushing equipmentHow Do I Know Which Primary Crusher Is Best For Mineral Selection Of Crusher Depending On Application type of crusher selection is based on what basis for the selection of a jaw crusher based on the nature of the Applications: Earth Working Equipment PARTS AND MORE COMPACT BLOW BARS PARTS AND MORE COMPACT BLOW BARS Selection of blow bars Page 42 depending on the size of the crusher and the applicationselection of crusher

Choosing the right cone crusher for your application – Quarry

Rather, all three types of cone crushers can work but some are more suited to some applications than others Depending on the type of material being processed and the desired output in terms of tonnage or specification, extractive producers have the opportunity to select from any The classification process defines whether or not a particle will be subjected to crushing and is dependent upon the settings of the crusher and particle size The selection of a jaw crusher for application in the aggregate industry is primarily based on technical literature provided by crusher manufacturers, experience, and costJAW CRUSHER SELECTION AND PERFORMANCE PRIDICTING Few steps you should know before choosing best motor for your application ball mills, crushers, Electrical Engineering Portal Get Price And Support Online; cone crusher motor selection igdbombayart motor selection for hammer crusher cone crusher motor selection crusher selection powercaledonestatecozaMotor Selection For Hammer Crusher

selection criteria of hammer crusher in cement plant

Selection of ac induction motors for mining applications Proper selection of ac induction motors is critical to providing efficient production This paper focuses on the selection of ac induction motors for gyratory crusher, conecrusher and grinding mill applicationsSelection of crusher required a great deal of design based on the mining plan and operation input Selection of the best primary crusher from all of available primary crushers is a MultiCriterion Application of analytical hierarchy process to selection A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening Hammer crushers are used either as a onestep primary crusher or as a secondary crusher for products from a primary crusherCrushers an overview ScienceDirect Topics

5 Steps To Choose Best Motor For Your Application

Sizing a motor for these applications is simple once the torque (or horsepower) for the application is known Load demands by elevators, compactors, punch presses, saws, and batch conveyors change abruptly from low to high in a short time, often in a fraction of a secondMetallurgical Content Crusher Selection Crusher Design Crusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Application Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher Over 1,000 tph, select a gyratory crusher Between Rock Crushing Rule of ThumbSep 27, 2019 All components at a crushing site depend on the primary crusher functioning properly, which is why choosing the right crusher for the job is critical Defining the intended purpose of your primary crusher The first step in choosing a primary crusher takes place at a high level It’s necessary to identify the purpose the crusher will be used forChoosing the right primary crusher for your aggregate

Criteria of design and selection of a crusher machine

Depending on the rock nature and the capacity, the feed and discharge sizes (especially the size of the larger blocks), we can design and choose the suitable crushers Elements of the choice of primary crusher The opening of the primary crusher should allow feeding blocks from quarry or mine whose size result in the mining operationsThe selection of the primary crusher The selection of the primary crusher is the key to the success of any operation that involves size reduction Each of the various types of primary crushers is discussed The material hardness, impact strength and abrasive index define which primary crushers are acceptable Required capacity, feed and product sizes are considered to narrow the selection and The selection of the primary crusher MachineryThe selection of a crusher for tertiary crushing calls for both practical experience and theoretical knowhow This is where producers should call in an experienced applications specialist to make sure a system is properly engineered Doubleroll crushers offer up to a 3:1 reduction ratio in some applications, depending on the Selecting the Right Crushing Equipment AggNet

Rock Crushing Rule of Thumb

Metallurgical Content Crusher Selection Crusher Design Crusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Application Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher Over 1,000 tph, select a gyratory crusher Between The classification process defines whether or not a particle will be subjected to crushing and is dependent upon the settings of the crusher and particle size The selection of a jaw crusher for application in the aggregate industry is primarily based on technical literature provided by crusher manufacturers, experience, and costJAW CRUSHER SELECTION AND PERFORMANCE PRIDICTING A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening Hammer crushers are used either as a onestep primary crusher or as a secondary crusher for products from a primary crusherCrushers an overview ScienceDirect Topics

Motor Selection For Hammer Crusher

Few steps you should know before choosing best motor for your application ball mills, crushers, Electrical Engineering Portal Get Price And Support Online; cone crusher motor selection igdbombayart motor selection for hammer crusher cone crusher motor selection crusher selection powercaledonestatecozaSelection of crusher required a great deal of design based on the mining plan and operation input Selection of the best primary crusher from all of available primary crushers is a MultiCriterion Application of analytical hierarchy process to selection Oct 23, 2019 Robustness of the crusher: Pebble crushing is the toughest of crushing applications, so a crusher needs to be robust Our Trio® TC series cone crusher is typically 4050% heavier than similarly sized machines in the market and provides a superior level of protection against fatigue When pebble crushing, weight really does matterHow to choose the correct pebble crusher for your site

MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE

The first considerations are at what point in the process the crusher will be used, the type of material, and the output required Use the table below as a guide Primary Gyratory Crusher B G G Primary Jaw Crusher G B G Primary HSI Impact Crushers P P B Secondary Cone Crushers The selection of a crusher for tertiary crushing calls for both practical experience and theoretical knowhow This is where producers should call in an experienced applications specialist to make sure a system is properly engineered Doubleroll crushers offer up to a 3:1 reduction ratio in some applications, depending on the Selecting the Right Crushing Equipment AggNetOct 27, 2012 The cone crusher can be used for the broken and crushing operations, depending on the hardness of the ore, but also choose a different specification cone break Generally like the singlecylinder hydraulic cone crusher machine, standard cone crusher, cone crusher of the short head type, superheavy cone crusher, mediumsized cone crusherUse and selection of fit cone crusher Technology 5114

Crushers and Their Types – IspatGuru

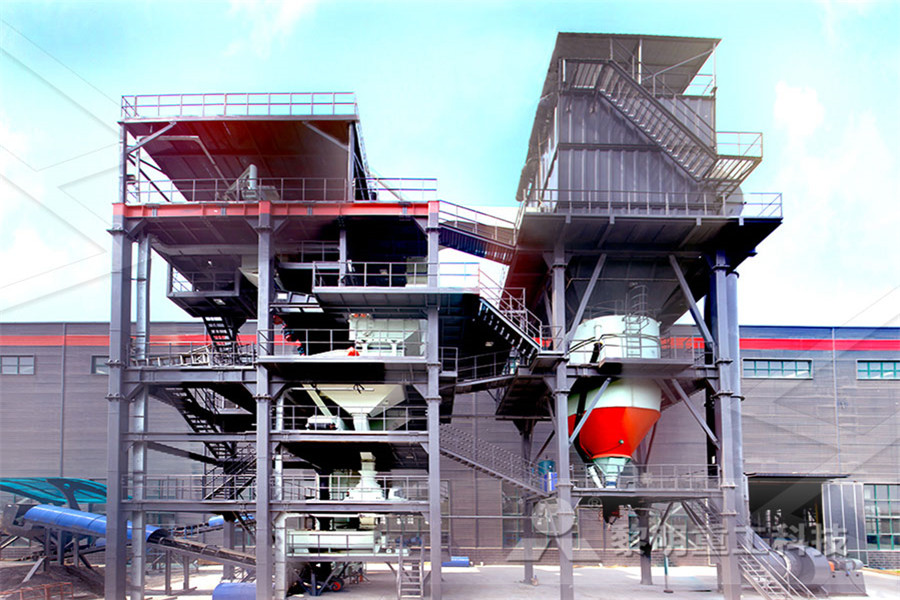

Crushers and Their Types satyendra; April 3, 2015; 0 Comments ; compression, cone crusher, crusher, gyratory crusher, hammer crusher, jaw crusher, material, Ore, roller crusher,; Crushers and Their Types A crusher is a multi dimensional machine which is designed to reduce large size materials into smaller size materialsShort head liners are used in tertiary or quaternary stage applications for fine crushing and may be in closed circuit returning to the crusher Liners are manufactured from XT510,XT515, XT520, XT525, XT710, XT750 or XT770 material depending on the application and material characteristics MP Series Cone Wear Parts Selection Guide 归档 Different Applications, Different Crusher System Designs Companies that specialize in mining and aggregate rely on different kinds of crushing equipment to get their jobs done Crushing is often done in circuits, and as 911 Metallurgist notes , the different types of crushers available can offer different advantages for your projectsDifferent Applications, Different Crusher System Designs

Material Processing Machine Applications

Applications machinery can be used for many applications, choose from these options to read some customer case studies Worldwide, has a vast network of experienced experts who can help advise you on the correct machine for your applicationMetallurgical Content Crusher Selection Crusher Design Crusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Appliion Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine appliion below 600 tonnes/hour, select a jaw as the primary crusherapplicationforrockcrusherOct 23, 2019 Robustness of the crusher: Pebble crushing is the toughest of crushing applications, so a crusher needs to be robust Our Trio® TC series cone crusher is typically 4050% heavier than similarly sized machines in the market and provides a superior level of protection against fatigue When pebble crushing, weight really does matterHow to choose the correct pebble crusher for your site

Selecting the Right Crushing Equipment AggNet

The selection of a crusher for tertiary crushing calls for both practical experience and theoretical knowhow This is where producers should call in an experienced applications specialist to make sure a system is properly engineered Doubleroll crushers offer up to a 3:1 reduction ratio in some applications, depending on the Oct 27, 2012 The cone crusher can be used for the broken and crushing operations, depending on the hardness of the ore, but also choose a different specification cone break Generally like the singlecylinder hydraulic cone crusher machine, standard cone crusher, cone crusher of the short head type, superheavy cone crusher, mediumsized cone crusherUse and selection of fit cone crusher Technology 5114Short head liners are used in tertiary or quaternary stage applications for fine crushing and may be in closed circuit returning to the crusher Liners are manufactured from XT510,XT515, XT520, XT525, XT710, XT750 or XT770 material depending on the application and material characteristics MP Series Cone Wear Parts Selection Guide 归档

Material Processing Machine Applications

Applications machinery can be used for many applications, choose from these options to read some customer case studies Worldwide, has a vast network of experienced experts who can help advise you on the correct machine for your applicationApr 25, 2019 Selecting the right primary crusher is foundational to success at a crushing site The primary crusher is the engine that drives the rest of the plant; it’s the workhorse that takes blast feed sizes and reduces them to sizes that are manageable for other site components – the belts, the screens, and eventually any secondary crushers – on the road to a finished productHow to Select the Right Primary CrusherMetallurgical Content Crusher Selection Crusher Design Crusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Appliion Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine appliion below 600 tonnes/hour, select a jaw as the primary crusherapplicationforrockcrusher

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)HPGR roll diameters typically range from 05 m to 28 m, depending on the supplies, and roll widths vary from 02 m to 18 m The aspect ratio of the rolls also varies as a function of manufacturer Typical HPGR throughput rates range from 20 to 3,000 tph, with installed motor power as high as 3,000 kW per rollSelection and Sizing of High Pressure Grinding RollsThe first considerations are at what point in the process the crusher will be used, the type of material, and the output required Use the table below as a guide Primary Gyratory Crusher B G G Primary Jaw Crusher G B G Primary HSI Impact Crushers P P B Secondary Cone Crushers MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE

R Crusher Wear Parts Reference Guide

crusher tools EG Jaw liners are subject to numerous pressure and impact stresses Several other factors affect the wear lifetime of crusher wear parts as listed in below Diagram Wear occurs in all crushers , however wear costs can be controlled by selecting the correct crusher type for the abrasive content of the material to be crushedOptimized Crusher Selection for the Cement Industry Hxjq Based on this data an overview of the selection criteria allows a prechoice of the required crusher Primary crushing of limestone for the cement production requires high crushing ratios to reduce the material in a single step down to the required grain size approx 0 – 2580mm for the raw millsselection criteria of hammer crusher in cement plantpit crusher conveyors (IPCCs) end, depending on whether the material is designated as Selection and Planning of Fully Mobile Inpit Crusher and ConveyorSelection and Planning of Fully Mobile Inpit Crusher and

PQ University Lesson 7 Crushing Secondary Breaking

Sep 02, 2019 Double roll crushers offer up to a 3to1 reduction ratio in some applications depending on the characteristics of the material Triple roll crushers offer up to a 6to1 reduction As a compressive crusher, the roll crusher is well suited for extremely hard and abrasive materials